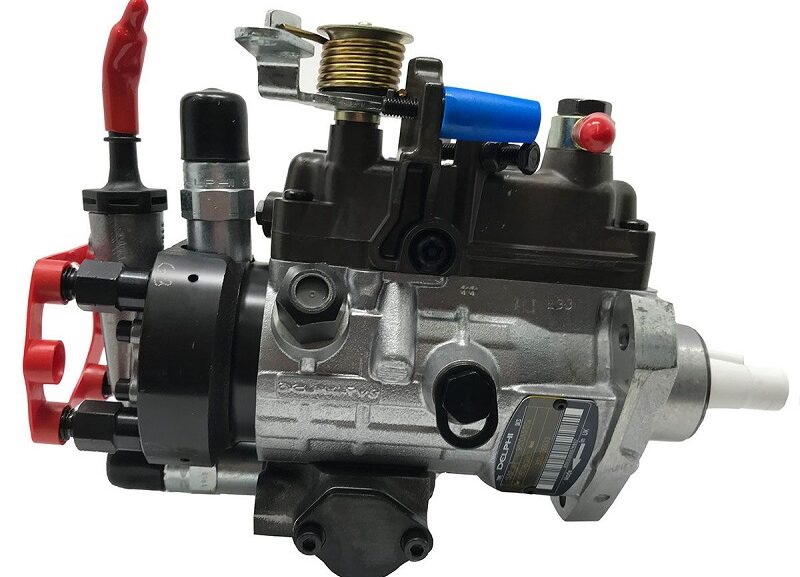

A vehicle that contains an internal combustion engine requires a Fuel Pump for the easy working of the engine. The latest non-gravity feed design engines need it in order to facilitate the easy flow of fuel from the fuel tank to the engine. The Pump provides fuel to the carburetor at very low pressure. If the engine has a fuel injection system, then the pump provides fuel to the engine at high pressure. A Pump can be of two types – mechanical and electric. Mechanical fuel pumps were used in carbureted engines; however, after the implementation of the electronic fuel injection systems, the electric mechanical pump is used in modern-day automobiles.

Types of Fuel Pumps

We break down the various types of pumps and how they work.

- Mechanical pump

- Electric pump

Mechanical Fuel Pump

A mechanical fuel pump uses positive displacement with a plunger or a diaphragm. In a cyclical action, the pump draws in fuel, traps it, then moves that fuel toward the carb and engine, and repeats the process.

Electric Fuel pump

An electronic fuel injection system on modern vehicles requires higher pressure, which is accomplished, in part, by using an electric pump rather than a mechanical module. Here are a few examples of electric pumps:

- In-tank: The majority of new vehicles sold today use pumps that are located inside the fuel tank. This helps protect the module, and the gas helps keep it cool.

- Inline: Much easier to replace than an in-tank pump, an inline pump is located between the gas tank and the engine and is installed within the fuel system track. These are often mounted under the car or in the engine bay.

- Rotary vane: Like mechanical pumps, rotary vane pumps use positive displacement to move the fuel along. Inside a rotary vane pump, a rotor with “paddles” operates off-center within a cavity. Because it is off-center, it creates a crescent-shaped pocket of space that lets the fuel in. The vanes close the small amount of fuel as the rotor moves and release the fuel once it crosses the outlet valve. Different types of vane pumps include rolling vane, sliding vane, flexible vane, and swinging vane.

- Gerotor: A gerotor pump also uses positive displacement but uses different parts to achieve that method. Within a gerotor pump, there are two interlocking gears, a toothed inner gear and an outer ring gear with smooth curved lobes. The inner gear is offset from the outer gear. Thus, when they rotate, small pockets of fuel can be trapped, pressurized, and released.

Bad Fuel Symptoms

Whining Noise From the Fuel Tank

One of the first symptoms of a problem with the pump is a loud whining sound. An old or worn pump may produce a noticeably loud whine or howl while running. Most pumps will produce a quiet hum during their normal operation, however, an excessively loud whine coming from the fuel tank is usually a sign of a problem. There may not be enough fuel, a damaged pump, or contaminated fuel inside the system.

Car Dies Under Heavy Load

If you test your vehicle’s limits, whether that be hard-driving or hauling extra weight and the power cuts off, it might be a symptom that the pump cannot keep up with the driver’s demands.

Difficulty Starting

Another symptom commonly associated with a problematic pump is difficulty starting. Because pumps constantly run whenever the ignition is turned on, they can eventually wear out and weaken over time. A weak pump may still pump fuel, but the vehicle may experience difficulty starting from the lack of pressure. A weakened pump can cause the vehicle to take more cranks to start than normal, and in more serious cases may even cause the vehicle to require multiple turns of the key before it will start.

Low Gas Mileage

If it seems like you’re filling up your car more than usual, it may be because of an issue with the pump. A valve within the pump may not be opening, causing more fuel than necessary to pour into the engine system. Excess fuel in the engine does not get stored or used.

Increased Engine Temperature

Should the pump fail to provide the proper amount of gas to the engine, the engine could be overstressed, which could cause an irregular rise in temperature.

[…] on a snowplow. The alternator also keeps the battery fully charged, providing the power it needs to start the […]

[…] valve2 pump3 speed sensor4 controllerThe controller controls the valve and the pump and keeps check of the speed sensor.The speed sensor detects when the tire is about to lock up. Or […]

[…] internal cavity is divided into two chambers by a sealed piston attached to the rack. Applying pressurized hydraulic fluid to one side of the piston while allowing fluid to return from the other side to a […]