Ring Piston: Definition, Function, Materials & Mechanism Explained

Posted on: April 21, 2025 | By: Muhammad Imran

Understanding the ring piston is crucial for anyone involved in vehicle maintenance, engine performance, or even choosing a reliable model like the Changan Deepal S07. While small in size, piston rings play an outsized role in determining your engine’s efficiency, power output, and long-term reliability.

This article breaks down the ring piston’s definition, types, functions, materials, positioning, and more. Whether you’re a vehicle owner, an auto enthusiast, or exploring service options like battery replacement, understanding this engine component will help you keep your car running smoothly.

What is a Ring Piston?

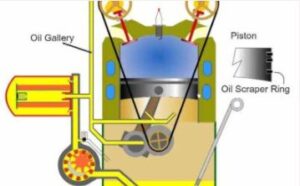

A ring piston refers to the circular metal rings fitted into grooves on the outer diameter of the piston inside an internal combustion engine. These rings create a seal between the piston and the cylinder wall, ensuring effective combustion, controlling oil flow, and facilitating heat transfer.

In Changan vehicles like the Karvaan MPV Plus 1.2 MPFI and Oshan X7 Comfort, ring pistons are engineered for reliability and performance, ensuring smooth and efficient engine operation.

Types of Piston Rings

-

Compression Rings – Seal the combustion chamber to prevent gas leakage.

-

Oil Control Rings – Manage the oil film on the cylinder wall, preventing oil from entering the combustion chamber.

-

Expander Rings – Work with oil rings to maintain ring tension.

-

Clamp Rings – Enhance contact between the ring and piston groove for better sealing.

-

Tool Rings – Require specialized tools for installation and are used in high-performance applications.

Functions of Ring Pistons

1. Sealing the Combustion Chamber

They prevent combustion gases from escaping into the crankcase, maintaining engine pressure and performance.

2. Heat Transfer

Piston rings conduct heat away from the piston to the cooler cylinder wall, avoiding overheating.

3. Oil Regulation

They scrape excess oil off the cylinder wall, maintaining a balanced lubrication layer for smooth operation.

Ring Piston Positioning & Installation

Proper piston ring positioning is essential for optimal performance. Incorrect ring placement can lead to poor compression, oil leakage, or stuck rings.

Tools You’ll Need:

-

Ring Compressor Tool – For compressing rings during piston installation.

-

Clamp Ring Tool – Helps position clamp-style rings.

-

Feeler Gauge – Measures piston ring gap clearance accurately.

Materials Used in Piston Rings

Piston rings are designed to handle extreme conditions, so they are made from highly durable materials:

-

Cast Iron – Excellent wear resistance and commonly used in standard engines.

-

Steel Alloys – Provide better flexibility and durability.

-

Coated Rings – Often layered with molybdenum or chromium for improved performance in high-stress conditions.

Signs You Need a Ring Piston Replacement

-

Blue smoke from the exhaust

-

Poor engine compression

-

Excessive oil usage

-

Engine misfiring

-

Loss of power or acceleration

If any of these symptoms appear, it may be time to replace your piston rings to avoid further damage. For newer models, check out the Changan Deepal S07 EMI Plan for an upgrade that brings both performance and affordability.

FAQs: Ring Pistons Explained

Q1: What is a ring piston?

A circular ring fitted around a piston to help seal the combustion chamber and regulate oil and heat flow.

Q2: What does a piston ring do?

It keeps combustion gases sealed, manages oil, and conducts heat from the piston.

Q3: What is a piston wear ring?

A wear-resistant ring designed to minimize friction and extend piston life.

Q4: What’s the working principle of a piston ring?

It expands and contracts within the cylinder to maintain a gas-tight seal as the piston moves.

Q5: What is the material of a piston ring?

Common materials include cast iron, steel alloys, and coatings like molybdenum.

Q6: What causes piston rings to fail?

Overheating, poor lubrication, wear and tear, and engine contamination.

Q7: How to check piston ring gap?

Insert the ring into the cylinder and use a feeler gauge to measure the gap.

Q8: Can you reuse piston rings?

Not recommended. Used rings may not maintain proper sealing.

Q9: How often should piston rings be inspected?

Typically every 60,000 to 100,000 kilometers or during major engine overhauls.

Q10: What is a ring compressor tool?

A device used to compress rings so the piston can be inserted into the cylinder.

Final Thoughts

Though hidden deep within the engine, the piston ring plays a powerful role in ensuring efficient engine operation, smooth driving, and reduced maintenance issues. Whether you’re driving a dependable workhorse like the Karvaan MPV Plus or upgrading to a more advanced option like the Changan Deepal S07, maintaining your engine’s internal health is key to maximizing performance and longevity.

Explore more at changansouth.com, where innovative engineering meets everyday reliability.